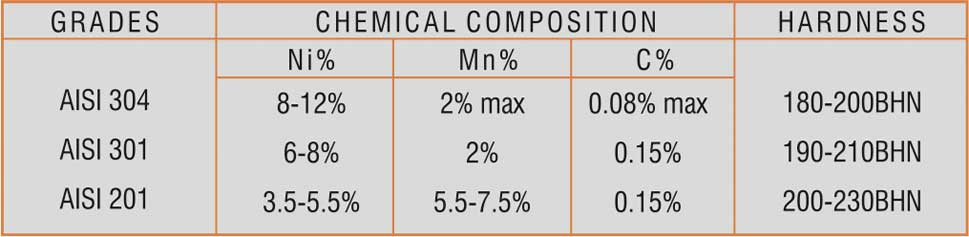

AISI 304 : Segments of this grade is deemed to be softest & very

ductile, since percentsge of Manganese is low & percentage of

nickel is higher, hence milling & grooving is much easier, consuming

less cutters & chaser. Annealing is done by heating in elevated

temperature and rapid cooling. A desired hardness is obtained by

either normalising or cold working. Internationally accepted as

CTC segments of Food Grade Quality.

Note: Pegging holes & pins are provided at customer's request free of cost.

AISI 301 : Moderately softer segments compared to AISI 304. Annealing & normaling carried out similar to AISI304. & equaly good for milling & grooving.

AISI 201 : Hardness moderately higher than AISI 301. but much more economical having longer life due to endurance. Milling grooving takes little more time than AISI 304 or AISI 301.